We encounter amorphous materials everywhere as plastics, window glass, and concrete. Their mechanical properties are central in many of their applications. Fracture presents a serious limit to their applications, demarcating failure of the material. In amorphous materials, slow fracture is of particular interest: in this fracture process, the material can develop cracks over long times, assisted by slow, plastic processes. This slow fracture process in is not well understood, and challenging to study with computer simulations due to the long time scales involved.

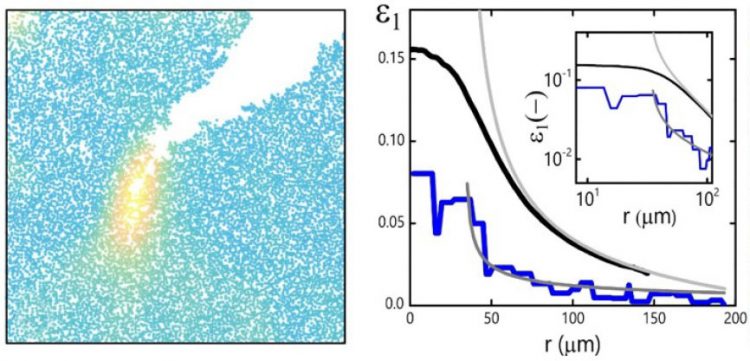

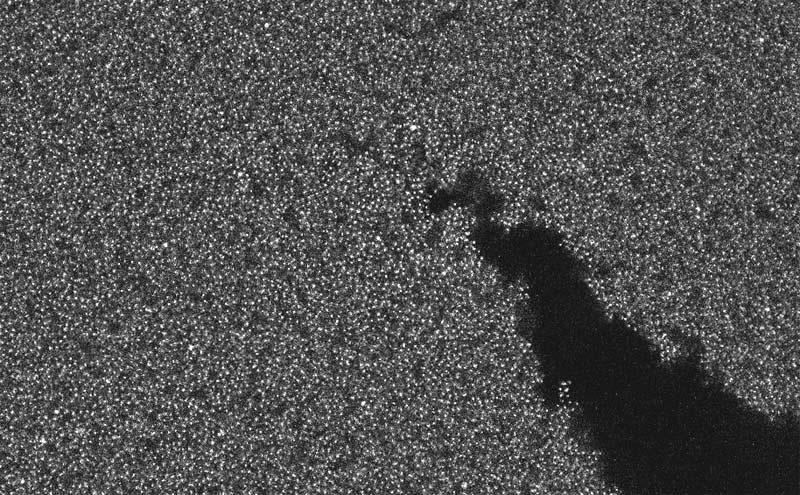

We achieve direct particle-scale images of the slow fracture process using a cohesive colloidal model system. In this system, the particles interact via attractive critical Casimir forces, producing a cohesive amorphous solid that exhibits fracture in very close analogy to atomic amorphous solids. The figures below show a microscope movie of the slow fracture experiment (Fig. 1), and the strain distribution, calculated from the displacements of the individual particles between subsequent frames (Figs. 2 and 3). These direct observations allow us to elucidate the origin of the highly intermittent dynamics of the fracture process due to the interplay of strain-induced weakening and crack propagation.